How to activate EM

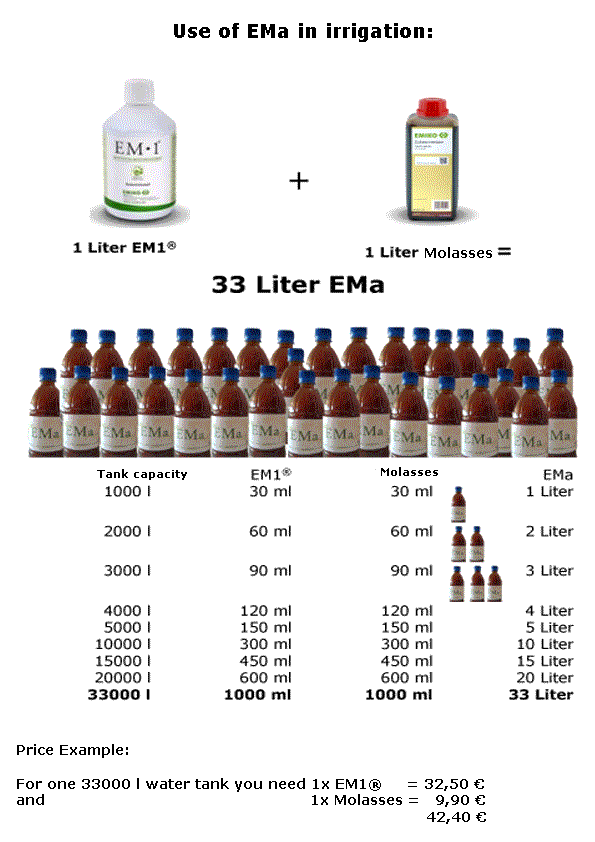

EM1 is the original microbial solution, which can be easily multiplied to an activated form. The effect of activated EM corresponds, with careful procedure (see the description below) to that of EM1. The difference is in the durability of activated EM and in the cost factor. 33 L activated EM can be produced from one liter of EM1.

Get the following accessories:

A clean PET water bottle or canister for storing the result of the activated EM

A clean PET water bottle or canister for storing the result of the activated EM- Water basin or a large bucket

- A metal podium as a thermal conductor (fululative)

- An aqarium heating pole

- “Gährspund”

- EM-X® – ceramic pipes

Follow these steps:

- Fill your selected ferment vessel to 1/3 with 80° C of good, hot water.

- Stir 3% sugar cane molasses (exact quantities in the table below) until it is completely dissolved.

- Fill the vessel with cold water until a temperature of 35 – 40 ° C is reached and add

4-6 EM-X ceramic pipes per liter. - Add 3% EM1® (exact quantities in the table below) and thoroughly mix the contents of the ferment.

- Fill the fermenter with 35 – 40 ° C warm water, close it and place the 3/4 water tank filled with 30 ° C.

- Put and connect the heater in the water tank, so that it doesn’t come into contact with the fermentation vessel and the water is stable at 32-35 ° C.

- Plut it in a warm place for 7 days and wrap it with a cloth to avoid temperature fluctuations.

- After 7 days the EMa is ready. The pH should be below 3.9 to 3.2 (test with pH indicators).

Mixing table for vessels of different sizes:

6 Setting the heating element

The temperature is adjusted by means of a rotatable setting wheel on the upper part of the heating element. Use a thermometer to check the water temperature. It should be held constant between 34 ° and 37 °.

7 Setting up the fermenter:

The fermenter should be in a place with a constant temperature. Optimal is a temperature range between 15 and 21 degrees Celsius. Temperature fluctuations during fermentation must be avoided. A cold bridge can, for example, be produced by tile or stone floors without floor heating. In this case, the fermenter can be placed on a styrofoam plate. A blanket wrapped around the outer walls of the fermenter or a towel keeps the internal temperature constant and saves electricity. The cover must not be wrapped.

The fermenter must be placed on a level surface. If it is tilted, the heating rod is not centered and temperature fluctuations in the tank may occur.

In case of a large fermenter with a stopcock, it must be taken into account that after the end of the fermentation, a vessel can be conveniently placed underneath the outlet cock in order to remove the finished EMa.

8 characteristics of a successful activated EM:

An EMa is ready and successful when it has a pH value below 3.6 and smells sweet and sour.

The color has not changed during fermentation and is still brown. White flakes on the activated EM are yeasts and belong to a good activated EM. Stable odors or higher pH values indicate that the composition of the microorganisms is incorrect and possibly negative germs have developed. The reason for this is 99% due to insufficient cleaning of the fermenter or strong temperature fluctuations during fermentation. Such an activated EM should be disposed of.

On the other hand, lower pH values do not give cause for concern as long as the smell and appearance are characteristic.

We are currently importing products for the production of activated EM from Germany.